Innovative.

Cost Effective.

Timely.

We strive to provide the most innovative and advanced ground engineering solutions.

With shrinking margins in these testing times, we tailor our solutions to minimize the cost wherever possible for our clients, adding value to their projects.

Time is of the essence and delays can have a detrimental effect on the client and project completion. Therefore, we offer solutions that can be executed in short span of time, complying with the project deadlines.

Our Specialized Techniques

We use specialized ground improvement techniques for soils with low bearing capacity where the existing properties cannot fulfill the desired requirements of the project design. These ground improvement techniques have numerous advantages from being cost effective to more environmentally friendly.

VIBRO COMPACTION

Vibro Compaction is a technique that compacts granular soils and rearrange the soil particulars into a denser state. The compaction is attained using depth vibrators, typically suspended from a crane.

Process:

- A vibrofloat (poker) is inserted into the ground at predetermined points under its own weight and water jets coming out of the vibrator nozzles.

- These vibrations and water jetting allow the granular soil particles to rearrange themselves.

- A clear depression is then seen at the top ground surface during the compaction process.

- A volume reduction has been observed during compaction process which largely depends upon the original soil void ratio and the degree of compaction.

- This reduction in volume can be compensated using imported clean granular soil.

Advantages:

- Environment friendly.

- Very low compressibility – post construction.

- Settlements are reduced and overall load carrying capacity of the soil is enhanced.

VIBRO REPLACEMENT

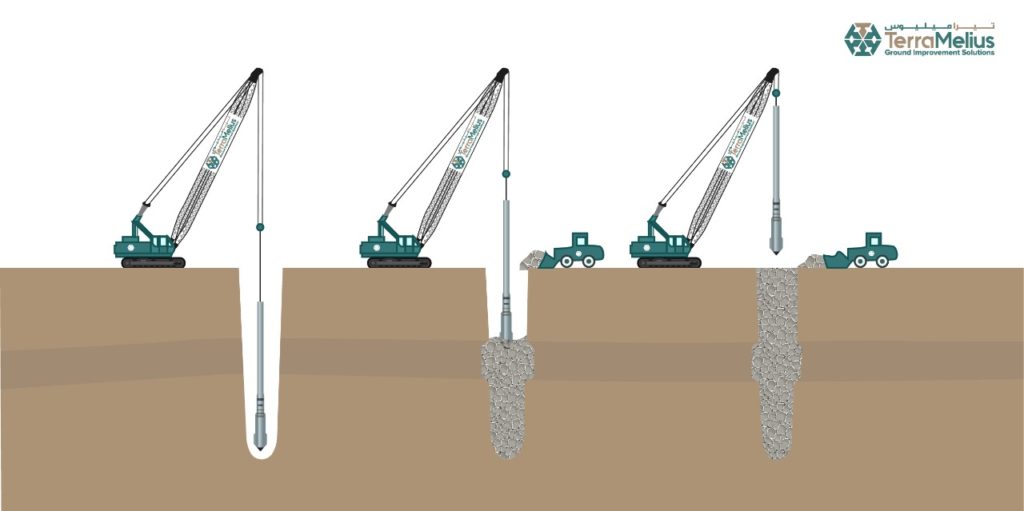

In this technique, load bearing columns are constructed that are made from gravel or crushed stones. The improved ground comprised of the stone columns and the surrounding soil will act as a single unit, capable of taking structural loads safely at the shallow depths. Stone columns are also used to mitigate the risk of liquefaction during seismic activity

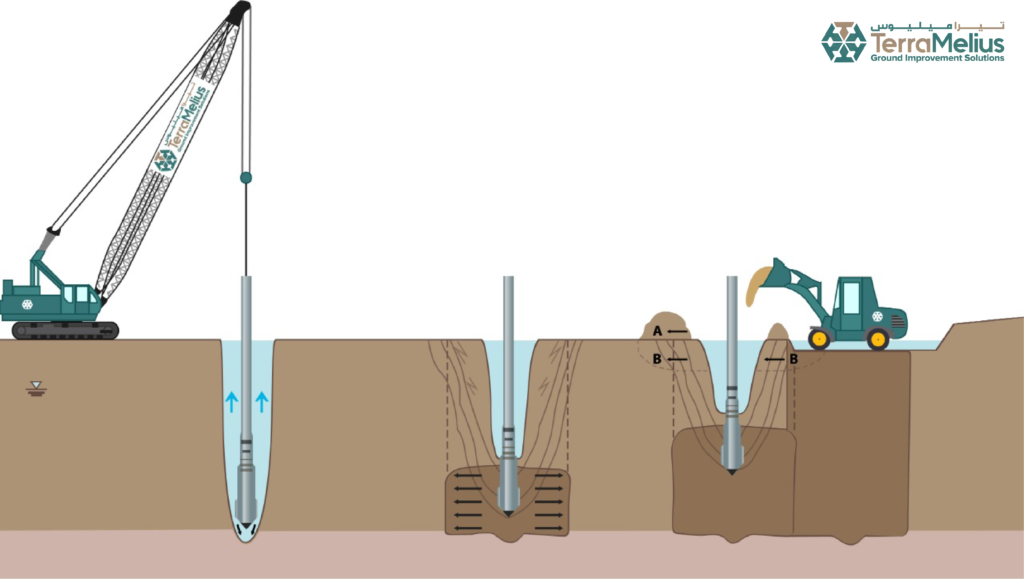

Process:

- The silty cohesive soils are non-responsive to the traditional compaction process. The soil particles tend to slide against each other. In order to improve the soil characteristics at shallow depths, vibro replacement technique has been devised.

- As the name indicates, the process involves in removing finer soil particles and replacing them with aggregates of size 25mm to 75mm.

- The process involves, making holes in soft cohesive soils using poker as shown in the photographs up to the required depths, washing out loose fine particles of the existing soil by using water jets coming out of the two nozzles of the poker.

- Once reached to the required depth, the poker is withdrawn up and using shovel loader, the stones are poured down the hole. The poker then moves down and up the hole and its vibratory action compacts the loosely filled stones.

- The aggregate is then filled and compacted until the poker reaches the working platform. This way, a well compacted stone column is formed.

- This process is repeated at each predetermined point, thereby making ground capable of taking structural loads safely at shallow depths.

- The improved ground comprised of the stone columns and the surrounding soil will act as a single unit, capable of taking structural loads safely at the shallow depths.

Advantages:

- Environment friendly as natural materials are used.

- Mitigate liquefaction potential.

- lateral spreading induced by earthquakes is prevented.

- Can be carried out to almost any depth.

- Cost effective, especially where ground water is high and traditional soil excavation and replacement methods are to be deployed.

- Best option for moderate loads.

- Construction can start immediately upon completion of stone column work.

RIGID INCLUSIONS

The increase of bearing capacity and settlement reduction are achieved through the reinforcement of the soft or loose soil layers using rigid inclusions. The scheme details a load sharing system combining the existing soil capacity and the stiffer rigid inclusions to ensure compliance with project specifications.

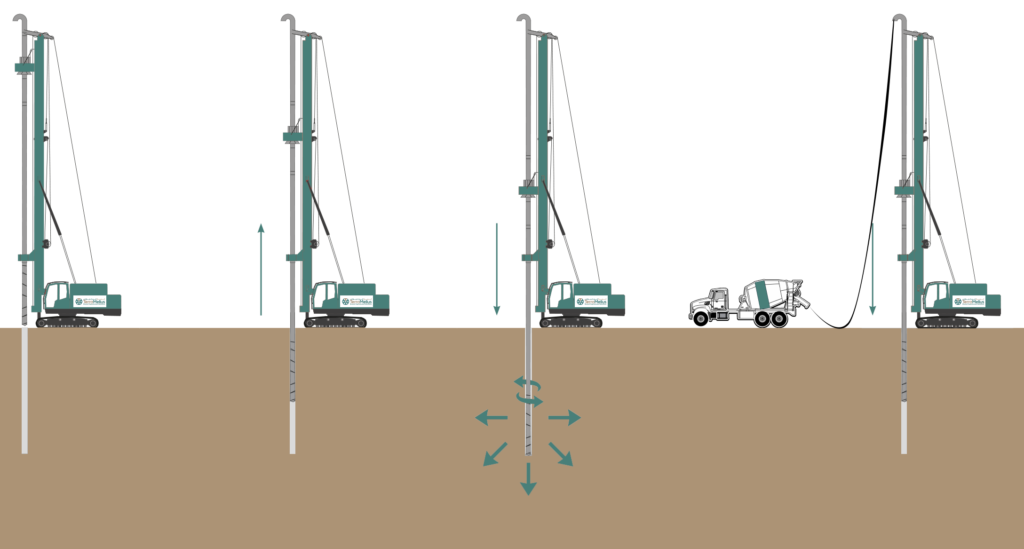

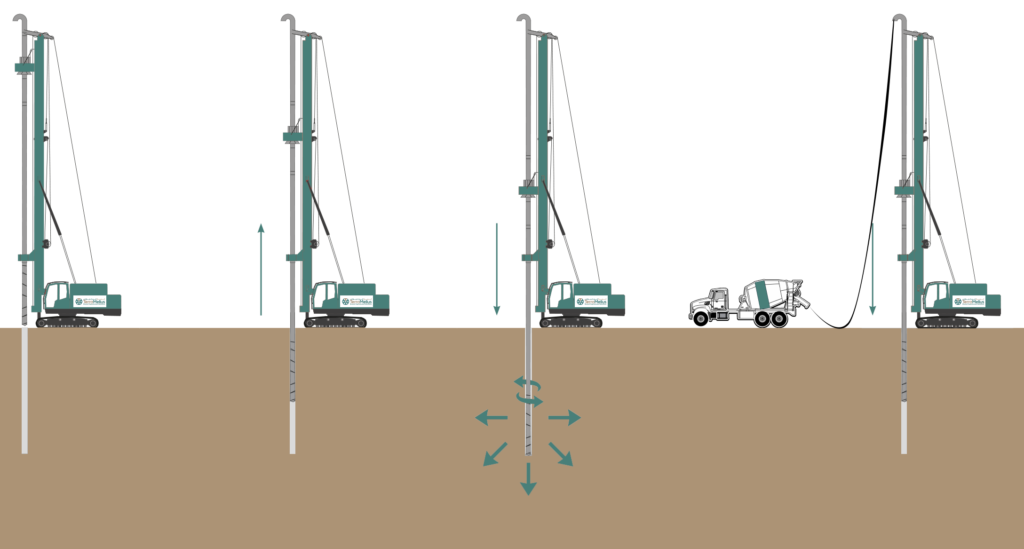

Process:

- Rigid Inclusions can be installed using several technologies. The most common is, using Continuous Flight Auger (CFA) or Displacement Piles.

- The operating phases entails the formation of piles by driving a Continuous Auger, assembled on a central hollow pipe.

- Once reached the designed depth, the Concreting/ grouting is done simultaneously through the hollow pipe connected to the pump, which pumped the concrete/grout, down the drilled hole.

- At the same time, the CFA is pulled up and the soil within the blades of the Auger comes out, allowing concrete to cover the complete drilled hole, making an unreinforced concrete/ grout pile.

Advantages:

- Improve the loose soil condition

- Enhance the Bearing Capacity as a unit ( comprised of soil and the RI )

- Reduce post construction settlement (Hence will deliver safe ground for future construction work)

- Can work close to adjacent structures as the vibrations generated during the work are non-existent

- Can work close to residential areas as noise generated during construction in minimal

BORED PILES

Process:

Piles foundations is used when the structure loads are very high and the soils at shallow depths are not suitable to take that loads without undergoing excessive settlement. Different types of piles are in used , world wide to transmit the heavy loads to deeper depths safely. Most common type of piles used in this part of the

world is , Bored cast in place place piles.

Advantages:

- Cater for heaviest of the structure loads safely

- Can be constructed to any depth

- Ideal foundation solution for High Rise Buildings/ Flyovers/ Transmission Towers/Metro Rails etc